[Focus on people’s livelihood, keep warm and ensure supply] Numerical intelligence empowers China Electric Power Technology to provide technical support for keeping warm and ensuring supply – State-ow

With the opening of the central heating curtain, many places have officially entered the "heating time". China Electric Technology’s digital intelligence solutions are widely used in energy, power and other industries to provide technical support for keeping warm and supply, and to send "warm happiness" to the people.

Walking into the smart heating network dispatching command center, on one side of the large screen, the total amount of steam supply, total steam consumption, total heat supply, total heat consumption, energy consumption analysis, alarm information, etc. The on-site staff monitored the data and carefully recorded the operating indicators… This is the "smart brain" of Shiyan City’s winter heating.

"Compared with traditional heating, smart heating emphasizes the application of emerging technologies such as the Internet of Things and big data." According to technical experts from China Electric Technology, the company’s innovative "TECO Industrial Internet + Smart Heating Network" not only performs digital intelligent transformation of pipelines, equipment, meters, control and regulation equipment in the heating system, but also introduces technologies such as the Internet of Things and big data. It independently develops the DataKeeper industrial data platform and builds more than 20 models such as a network hydraulic calculation model, a heating load prediction model, and a cost accounting model, allowing the dispatching center to accurately and real-time understand every aspect of heating, and even provide services more efficiently according to the needs of each household.

Make the heating system smart. "This’source-network-station-household ‘intelligent scheduling mode makes the heating station start and stop with one click, unattended, and promotes the refined and energy-saving operation of the heating system." According to technical experts from China Electric Technology, the system meets the smart heating demand of the 860-ton/hour steam heating system, reducing the heat consumption per unit area by nearly 10%, reducing the heating network loss by 12%, and comprehensively improving the heating capacity and service level.

"The power supply of the system is normal, so we can rest assured. The weather is so cold, we dare not have any problems with heating." In the cold winter, electric heating, as an efficient and environmentally friendly heating method, is increasingly accepted by the majority of users.

In order to protect the safe conversion of each kilowatt-hour of electricity, the intelligent inspection system of power plants supported by China Electric Power Technology has realized the digital upgrade of inspection work and made full preparations for the peak heating electricity consumption in winter.

In the fuel area, the intelligent inspection system can calculate the cross-sectional volume of the coal pile on the belt before and after entering the coal drop pipe, compare the coal volume passing through the inner belt per unit time, and determine whether the phenomenon of coal blocking and coal spilling occurs. The management staff will be notified as soon as possible to deal with it. The addition of multi-dimensional sensing technologies such as video and laser allows the symptoms of belt tearing to be detected in time at the early stage. In the production area with a more difficult environment, intelligent machines, intelligent cameras, thermal imaging online temperature measurement equipment and video intelligent analysis are "stationed" 24/7, not only to achieve "visible" temperature measurement, but also to solve the annoying "running and dripping" problem with intelligent IoT technology.

Gas is ignited, electricity becomes heat, and these energy sources have "traveled" thousands of miles when they are used. In the process of electricity and gas transmission, they often pass through the transit hub – the station valve chamber. For the station valve chambers that are often built in remote areas, China Electric Technology uses digital technology to build an intelligent sensing system to solve the needs of buried pipeline leaks "not visible", gas leaks "not audible", and manual quick judgment.

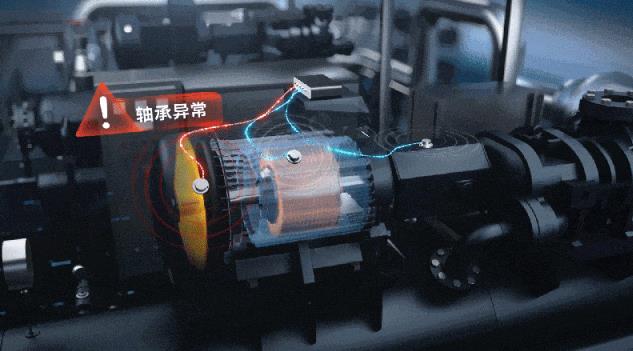

"The station valve chamber plays an important role in the networking and control regulation of long-distance pipelines, but over time, there will be leaks and leaks." According to technical experts from China Electric Technology, manual inspections often encounter problems such as real-time monitoring difficulties and difficulty in judging hidden dangers. The self-developed positioning-type vibration optical fiber senses the environmental status around the pipeline in real time, and sends an early warning signal in time when there is an external force touch. The positioning-type temperature measurement optical fiber senses the temperature change of the pipeline in real time, and judges and locates the leakage of gas and liquid in the pipeline. Industrial auscultation microphones, sonographs, etc., extract mechanical voiceprints in real time, intelligently judge the status and fault type of equipment, and fully safeguard the safety of energy pipelines.

[Editor in charge: Yu Zhaojun]