Focus on the two sessions in 2021: depicting the foreseeable future

This year marks the 100th anniversary of the founding of the Party in the Communist Party of China (CPC), and it is also the first year of the 14th Five-Year Plan. China will start a new journey of building a socialist modern country in an all-round way and March towards the goal of the second century. The China two sessions, which are at an important historical intersection, are worth looking forward to.

Aspect 1: Government Work Report and People’s Livelihood List

· Employment: give policy support to enterprises that don’t lay off employees and lay off fewer employees, and accelerate the pilot project of occupational injury protection.

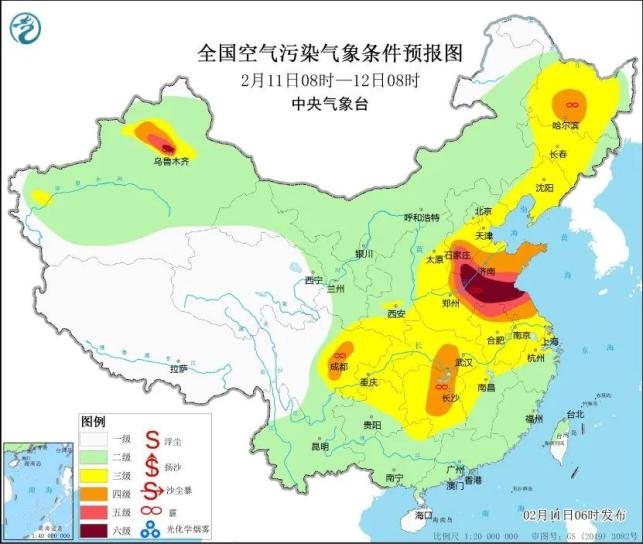

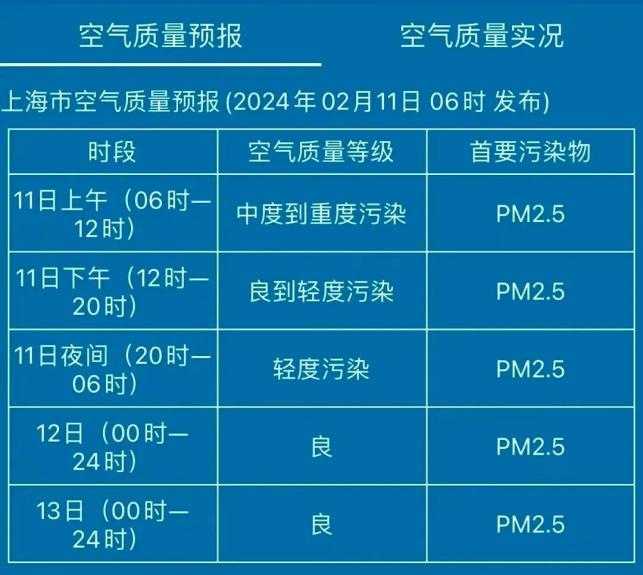

· Ecological environment: Strengthen the coordinated control of fine particles and ozone, and the clean heating rate in the northern region will reach 70%.

· Education: Improve the guarantee mechanism of inclusive preschool education to better solve the problem of schooling for children of migrant workers.

· Medical care: the per capita financial subsidy for residents’ medical insurance will be increased by 30 yuan, and the county-level medical service capacity will be improved.

· Coping with aging: the participation rate of basic old-age insurance will be increased to 95% in the next five years, and the legal retirement age will be gradually delayed.

· Consumption: increase residents’ income through multiple channels, and speed up e-commerce and express delivery into rural areas.

· Housing: solve the outstanding housing problems in big cities and help new citizens and young people to alleviate their housing difficulties.

· Rural revitalization: ensure that large-scale return to poverty does not occur, resolutely curb the "non-agricultural" of cultivated land and prevent "non-grain"

Aspect 2: Selected proposals of entrepreneurs’ two sessions

· Dong Mingzhu: The tax threshold is raised to 10,000 yuan. Raising the "tax threshold" can effectively improve the real income level of residents, and making people have money to spend is the driving force to promote consumption and drive the "internal circulation" of the economy.

· Ma Huateng: Support the new employment pattern. The new employment form has the characteristics of large employment capacity, low entry and exit threshold, strong flexibility and part-time job, forming a "reservoir" and a "buffer". It is suggested to further improve the relevant supporting mechanism and service system of the new employment form.

· Lei Jun: Let the elderly integrate into digital life. Promote the digital service for the elderly to be incorporated into the national information infrastructure construction as soon as possible, know how to establish an aging standard system for smart technology, and promote the integration and development of smart technology aging scenarios and emerging formats.

· Yu Minhong: The residence is nearby. It is suggested that in the Compulsory Education Law, "ensuring school-age children and adolescents to enter the school nearby where they live" be amended as "ensuring school-age children and adolescents to enter the school nearby where they live".

· Zhang Jindong: Establish a data sharing platform. Strengthen the top-level design, establish a data governance Committee, and establish a national data sharing platform.

· Zhou Hongyi: Pay attention to the safety of smart cars. It is suggested that the networked safety protection system of smart cars should be incorporated into the vehicle production, sales and service system, and gradually form mandatory requirements.

Anti-epidemic express

NEWS

More than 370,000 cases have been diagnosed globally, with a cumulative total of over 117 million cases.According to the real-time statistics of the Worldometer website, as of 6: 30 on March 8, Beijing time, there were 117,420,781 cases of COVID-19 diagnosed and 2,604,490 deaths. There were 376,633 new confirmed cases and 5,893 new deaths worldwide in a single day.

Chief scientist of the World Health Organization: Nearly 10% of the world’s population has Covid-19 antibodies.

According to Sputnik’s report on March 1st, Sumiya Swaminathan, chief scientist of the World Health Organization, said that nearly 10% of the world’s population already has Covid-19 antibody, and continued vaccination is the only way to achieve "collective immunity".

Zhong Nanshan Dialogue Fauci: It will take at least 2 ~ 3 years for the whole world to achieve group immunity.

On March 1st, at the forum of "Fast Recovery on the Right Track: Sino-US Cooperation in Prevention, Control and Treatment of COVID-19 Epidemic", Zhong Nanshan, the head of National Health Commission’s high-level expert group, said that group immunization can’t be achieved by making a large number of people sick, and it must be achieved through vaccination based on science. Global mass immunization takes at least 2-3 years, or even longer. However, in China, 60 different vaccine projects are currently under way, and 6 of them have entered the third phase of clinical practice.

WHO: The idea of ending the epidemic before the end of this year is unrealistic.

On March 1st, local time, Michael Ryan, the head of WHO’s health emergency project, said that it was unrealistic to end the epidemic before the end of the year, and it was still too early. It was wise to reduce the number of hospitalized cases as much as possible, which was a tragedy caused by the COVID-19 pandemic.

Boeing said that the impact of the COVID-19 epidemic on its global aircraft delivery will last for up to 10 years.

On March 4th, David Schulte, managing director of Boeing’s commercial aircraft marketing business in India, Southeast Asia and Asia Pacific, said that the COVID-19 epidemic "will definitely have an impact on our expected delivery volume in the next decade." Schulte said that globally, due to the grounding of many old aircraft during the epidemic, the fleet retirement rate of airlines is expected to double from 2% to 3% to about 5%.

Sweden reported a case of COVID-19 infection in the mother’s womb.

Xinhua News Agency, Stockholm, March 4, Swedish researchers recently published a report in the British Journal of Obstetrics and Gynecology, saying that a study on a pregnant woman who underwent emergency cesarean section and related newborns showed that the fetus had been infected with Covid-19 in the mother’s womb.

Disease control experts: the vaccine protection time limit is not only half a year.

How long is the protective prescription of COVID-19 vaccine? On March 4th, Pang Xinghuo, deputy director of the Beijing Municipal Center for Disease Control and Prevention, said in an interview that the protection period of COVID-19 vaccine is not only half a year, but because the vaccination time is still very short, and there are only half a year’s data at present.

Ministry of Foreign Affairs: China has exported about 43.85 billion masks to the United States.

The Ministry of Foreign Affairs said on March 5 that from March 1, 2020 to February 28, 2021, China exported about 43.85 billion masks to the United States. China is willing to continue to work together with all countries in the world, including the United States, to strive for an early victory over the epidemic.

WHO: COVAX has delivered more than 20 million doses of COVID-19 vaccine to 20 countries.

The World Health Organization said on March 5th that the COVID-19 Vaccine Implementation Plan (COVAX) jointly launched by it and its partners has delivered more than 20 million doses of vaccines to 20 countries, and another 31 countries will be delivered next week.

Tedros Adhanom Ghebreyesus, Director-General of WHO, warned that the collective trauma of the COVID-19 epidemic was greater than that of World War II.

According to the website of the US Consumer News and Business Channel reported on March 5, WHO Director-General Tan Desai said at a news conference that day: "After World War II, the world experienced collective trauma, because World War II affected the lives of many people. Now, the impact of the COVID-19 epidemic is more serious, and more people’s lives have been affected. Almost the whole world has been affected, and in fact everyone in this world has been affected. " He also said: "This means collective trauma, even greater than what the world experienced after World War II."

Policy voice

NEWS

Ministry of Industry and Information Technology: China has become the largest manufacturing country for 11 consecutive years

On March 1, Xiao Yaqing, Minister of the Ministry of Industry and Information Technology revealed at the press conference on the development of industry and informatization held by the State Council Office that China’s industrial added value increased from 23.5 trillion to 31.3 trillion, making it the largest manufacturing country in the world for 11 consecutive years. The proportion of manufacturing industry contributes nearly 30% to the world manufacturing industry.

Guangdong set up Greater Bay Area Competition Policy Committee to prevent disorderly expansion of capital.

People’s Daily reported on March 2nd that recently, the website of Guangdong Provincial People’s Government released the Implementation Plan for Guangdong Province to Further Promote Competition Policy in Guangdong-Hong Kong-Macao Greater Bay Area, which mainly included the establishment of the Competition Policy Committee of Guangdong-Hong Kong-Macao Greater Bay Area City, Guangdong Province, the full implementation of fair competition review system, and the strengthening and improvement of anti-monopoly law enforcement.

Guo Shuqing: Strengthening anti-monopoly and preventing disorderly expansion of capital.

On March 2, Guo Shuqing, President of China Banking and Insurance Regulatory Commission, said at the press conference of the State Council Office that 2021 is the first year of the 14th Five-Year Plan, and China Banking and Insurance Regulatory Commission will take risk prevention as the eternal theme of the financial industry, monitor and resolve all kinds of financial risks relentlessly, strengthen the financial rule of law and improve the long-term mechanism. Maintain a fair competitive market environment, strengthen anti-monopoly and prevent disorderly expansion of capital, and ensure that financial innovation is carried out under the premise of prudence.

General Administration of Market Supervision: Five community group purchases were subject to administrative punishment.

On March 3, according to the official WeChat of the General Administration of Market Supervision, it was found that there were unfair price behaviors such as low-price dumping and price fraud in community group buying enterprises such as Orange Heart Optimization (Beijing) Technology Development Co., Ltd. and Wuhan Seven Delicious Technologies Co., Ltd. Four community group-buying enterprises, including Orange Heart Optimization (Beijing) Technology Development Co., Ltd., were given an administrative penalty of 1.5 million yuan, and Wuhan Qiwei Delicious Technology Co., Ltd. was given an administrative penalty of 500,000 yuan.

National Forestry and Grassland Administration: China will draw up the "14th Five-Year Plan" for wildlife protection.

On March 3rd, China. com reported that it was learned from the National Forestry and Grassland Bureau that China will study and compile the "Tenth Five-Year Plan" for wildlife protection, formulate special protection plans for key species such as gibbon and pangolin in Hainan, and accelerate the adjustment of the List of Terrestrial Wild Animals with Important Ecological, Scientific and Social Values and the assessment and identification of important habitats of terrestrial wild animals.

Beijing prohibits schools from participating in the operation and cooperation of "small dining table"

On March 3rd, Beijing Municipal Education Commission, Municipal Market Supervision Bureau and Municipal Health and Health Commission jointly issued a document stating that by the end of 2021, schools, kindergarten canteens and student meal distribution enterprises will basically realize "internet plus’s bright kitchen". Students’ afternoon and after-school activities are included in the full-time management of the school, and the system of going out for leave when eating outside the school is implemented. It is strictly forbidden for the school to participate in the operation and cooperation of the social "small table" in any form.

Hebei issued a notice: Xiong ‘an plans to afforest 25,000 mu this year.

On March 5 th, recently, the General Office of the People’s Government of Hebei Province issued a notice on the task of afforestation in 2021, and the task of afforestation in the province in 2021 was 6 million mu. Among them, xiong’an new area will afforest 25,000 mu.

The Ministry of Transport talks about Didi Company: earnestly fulfill the main responsibility of the enterprise and protect the legitimate rights and interests of drivers and consumers.

On March 6 th, according to the Ministry of Communications, the responsible comrades of the Inter-Ministerial Joint Conference Office for Collaborative Supervision of New Transportation Forms had an interview with Didi. The interview pointed out that Didi Company’s recent preparations for adjusting its business strategy in some cities were not sufficient, and communication and evaluation were not in place, which was suspected of infringing on the legitimate rights and interests of drivers and was widely concerned by the society.

Enterprise practice

NEWS

C919 passenger plane officially landed in the world!

On March 1st, China Eastern Airlines (600115, Share Bar) Group Co., Ltd. and China Commercial Aircraft Co., Ltd. formally signed the purchase contract of C919 large passenger aircraft in Shanghai, which is also the first formal purchase contract of domestic large aircraft C919 in the world. China Eastern Airlines will become the first airline in the world to operate C919 large passenger aircraft.

Li Yanhong issued a document on financing innovation: promoting high-quality economic development

On March 2nd, Li Yanhong, Chairman and CEO of Baidu, published a signed article "Promoting High-quality Development by Financing Innovation" in People’s Daily, saying that under the background of a new round of scientific and technological revolution and accelerated evolution of industrial transformation, financing innovation has become a conscious subject of innovation. Baidu will continue to open up its sources, increase its investment in personnel training, promote more and more industries to achieve intelligent industrial upgrading, and inject more vitality into high-quality development.

Volvo Cars Releases Sustainable Development Strategic Objectives

On March 2, at the sustainable development strategy conference held by Volvo Cars, Volvo Cars announced its strategic goal of sustainable development in the future-in 2025, the proportion of pure electric vehicles of Volvo Cars will reach 50%, and the rest will be hybrid vehicles; In 2030, it became a pure electric luxury car enterprise; In 2040, it became a climate zero-load benchmarking enterprise; All pure electric vehicles will be sold online.

Alibaba will cooperate strategically with New Hope in agriculture and cultivate 200,000 new farmers in three years.

On March 2, it was reported that Alibaba and New Hope were brewing strategic cooperation in the agricultural field. The two sides plan to jointly build a new type of e-commerce business entity and cultivate 200,000 new farmers nationwide within three years. The No.1 project of cooperation between Ali and New Hope is the "First Kilometer" project. The two sides plan to jointly introduce high-quality resources of agricultural scientists and focus on the "stuck neck" problem in key agricultural fields.

Sany Group spent 100 million yuan to reward meritorious employees.

On March 2, it was learned from Sany Group that at the "Sany Festival Commendation Meeting" held on February 28, 4,195 employees, 6 earthquake-resistant and disaster-resistant heroes and 33 gold medal employees of Sany Group won a total of nearly 100 million yuan. At the same time, Liang Wengen, chairman of Sany Group, promised that when the total market value of listed companies under Sany Group reached 1 trillion, every "gold medal employee" would be rewarded with 5 million yuan.

Tencent released the first self-developed robot dog Max.

On March 3 rd, Tencent officially released the first multi-modal quadruped robot dog Max, which is fully developed in software and hardware. It adopts the integrated design of foot and wheel, has the specialty of "walking steadily on rough roads and running fast on flat roads", and can also stand on both legs to "pay a new year’s greeting".

Huawei executives responded to rumors of getting involved in pig raising: Do not raise pigs, empower enterprises to raise pigs with AI.

On March 4th, Duan Aiguo, president of Huawei Machine Vision, responded in an interview that Huawei does not raise pigs, but empowers enterprises to raise pigs. He believes that the application of AI in pig enterprises is still in a very backward state compared with other industries. "There are also large pig companies that have taken the initiative to find us and hope to use technology to empower the pig industry together."

BYD notified the company of 10 typical anti-corruption cases.

On March 4th, BYD (002594, Share Bar) released 10 typical anti-corruption cases in the fourth quarter of 2020 through its official WeChat WeChat official account "Clean BYD", including employees accepting meals and accepting kickbacks and bribes. For employees who violate the relevant provisions of BYD’s integrity, the company will not only terminate the labor contract, but also input their information into the delisting inquiry system; Units that violate the integrity cooperation agreement shall be investigated for corresponding responsibilities according to the agreement; Acts suspected of violating the law and committing crimes shall be resolutely handed over to judicial organs for handling.

Chairman China State Railway Group Co.,Ltd.: In 2025, the high-speed rail will cover 98% of the cities with a population of more than 500,000.

On March 6 th, recently, Lu Dongfu, deputy to the National People’s Congress and chairman and party secretary of China State Railway Group Co.,Ltd., said in an interview with People’s Daily that the scale of projects under construction and approved during the 14 th Five-Year Plan has reached 3.19 trillion yuan; By 2025, the national railway mileage will reach about 170,000 kilometers, including about 50,000 kilometers of high-speed rail (including intercity railway). Railways basically cover cities with urban population of more than 200,000, and high-speed rail covers 98% of cities with urban population of more than 500,000.

Social livelihood

NEWS

China Consumers Association released a public opinion report on consumer rights protection during the Spring Festival: amusement facilities are more negative.

China Consumers Association released a public opinion analysis report on consumer rights protection during the Spring Festival on March 1st. The report pointed out that although the information of "consumer rights protection" showed a curve fluctuation trend during the monitoring period, the daily number of related public opinions was relatively balanced. This year’s "Spring Festival" holiday consumption negative information is mainly concentrated in amusement facilities, movie viewing services, fireworks display and other aspects.

In 2020, the number of patent applications in China ranked first in the world.

On March 2, local time, the World Intellectual Property Organization released the latest report that the number of international patent applications submitted through the World Intellectual Property Organization will continue to grow in 2020. The number of patent applications in China increased by 16.1% year-on-year, ranking first in the world with 68,720. Followed by the United States, the number of patent applications reached 59,230. Japan, South Korea and Germany ranked third, fourth and fifth.

Peking University received 1 billion yuan in personal donations.

On March 3rd, Li Yongxin, Chairman of Zhonggong Education (002607, Share Bar) Group, donated 1 billion yuan to Peking University to set up the Peking University Zhonggong Education Development Fund. This is the largest personal donation since Peking University was founded, and it is also the largest alumni donation. Previously, Li Yongxin had donated 180 million yuan to Peking University.

China’s winter paralympic Olympic mobilization has developed to a thousand people.

March 4th is the first anniversary of the countdown to the opening of the Beijing Winter Paralympics. On the same day, Zhang Haidi, member of Chinese People’s Political Consultative Conference and executive chairman of BOCOG, revealed that the number of athletes in China’s Winter Paralympics has grown to thousands.

China’s 500-ton engine has been successfully tested in full-condition semi-system

On March 5th, the semi-system test run of the 500-ton liquid oxygen kerosene rocket engine developed by the Sixth Institute of Aerospace was a complete success, and a new breakthrough was made in the development of China’s heavy-duty launch vehicle engine.

International information

NEWS

British people eat an all-time high number of eggs, eating nearly 8 billion eggs a year.

According to the British "Sun" reported on February 28th, in 2020, the British ate nearly 8 billion eggs, with a total value of nearly 1.2 billion pounds (about 10.8 billion yuan), a record high. There are about 67 million people in Britain, which is equivalent to one person eating 120 eggs a year.

The United Nations website publishes the sustainable development report of Guangzhou.

Guangzhou Daily reported on March 1st that recently, "The Road to Green Development of Vibrant, Inclusive and Open Megacities —— Report on Guangzhou Local Voluntary Statement of UN Sustainable Development Goals" (referred to as "Report") was published in the column of UN Sustainable Development Goals in official website. Guangzhou became the first city in China to publish the report on the UN website. The experiences that can be used for reference are included in this report, including Baiyun Mountain (600332, Guba) project, coastal ecological restoration project, Haizhu wetland quality improvement and biodiversity protection and restoration.

G20 research group on sustainable finance resumed.

China Business News reported on March 1 that recently, Italy, the presidency of G20, hosted the first video conference of G20 finance ministers and central bank governors in this year. The meeting agreed to resume the establishment of the G20 Sustainable Finance Research Group to study the financial risks brought by climate change, strengthen the disclosure of climate-related information and support the green transformation. The People’s Bank of China continued to co-chair the research group.

Japan’s largest IT company was born!

According to a report by the Japan Broadcasting Association on March 2, Z Holdings and Line Company, the parent companies of Yahoo Japan under Softbank Group, formally implemented business merger on March 1, and the largest IT company in Japan was born. It is reported that the new company has about 23,000 employees and a total of about 100 million users. The search and social media services are the largest in Japan, and the company also provides online services such as advertising, e-commerce and finance.

2021 Hurun Global Rich List released

On March 2nd, Hurun Research Institute released the 2021 Hurun Global Rich List. The list shows that there are 412 new billion-dollar entrepreneurs in the world, with a total of 3,228, a record high. Musk’s wealth increased by nearly one trillion yuan compared with last year, reaching 1.28 trillion yuan, making him the richest man in the world for the first time. Zhong Shanshan, a 67-year-old farmer from Nongfu Spring, became the first China entrepreneur to enter the top ten in the world with a wealth of 550 billion yuan, ranking seventh and becoming the richest man in Asia.

WHO reports that one fifth of the people in the world are hearing impaired.

On March 2, local time, the World Health Organization released the World Hearing Report. According to the report, at present, one fifth of the people in the world have hearing impairment, and hearing loss affects more than 1.5 billion people around the world. By 2050, it is estimated that one quarter of people will have hearing problems, and nearly 2.5 billion people will suffer from some degree of hearing loss, of which at least 700 million people will need rehabilitation services. WHO recommends that ear and hearing care services should be provided for all.

Tokyo Olympic Games will not receive foreign audiences.

According to Japan’s "Daily News" report, a number of related people revealed on March 3 that the Japanese government plans not to receive foreign audiences around the audience problem of this summer’s Tokyo Olympic and Paralympic Games, and is now coordinating this. The Japanese government will reach a final conclusion within this month after discussion with the International Olympic Committee and other relevant parties.

United Nations report: Strengthening engineering capacity is essential for sustainable development.

On March 4th, UNESCO held the celebration of 2021 "World Engineering Day for Sustainable Development" online and released the report. According to the report, strengthening engineering capacity is essential to achieve the goal of sustainable development. At the same time, the report analyzes the development trend of major regional and cross-regional engineering in the world under the fourth industrial revolution, and encourages the global engineering community to work together to meet various challenges and accelerate the realization of sustainable development goals.

UN report: 17% of global food is wasted.

On March 5th, the United Nations Environment Programme (UNEP) estimated in the latest "Food Waste Index Report 2021" that in 2019, 931 million tons of food in the world were sent to the trash cans of families, retailers, restaurants and other food service enterprises, accounting for 17% of the total food available to consumers.

The proportion of female parliamentarians in the world has reached a record high.

According to the UN website, the Inter-Parliamentary Union recently said on the occasion of International Women’s Day on March 8 that in 2020, the proportion of women among parliamentarians in the world exceeded 25%, a record high, but there is still a considerable distance from achieving the goal of gender equality.

Today is March 8th International Women’s Day, I wish CSR divines a happy holiday, and we will share the responsibility in the future and ride the wind and waves.

This article first appeared on WeChat WeChat official account: Golden Bee. The content of the article belongs to the author’s personal opinion and does not represent Hexun.com’s position. Investors should operate accordingly, at their own risk.

(Editor: Wang Zhiqiang HF013)